Introduction

Lighting Power Density (LPD) is a critical metric in sustainable building design, representing the amount of electrical power used for lighting per unit area, typically measured in watts per square foot or square meter. It serves as a benchmark for evaluating the energy efficiency of lighting systems in residential, commercial, and industrial spaces.

LPD plays a pivotal role in promoting energy efficiency by helping designers and engineers minimize unnecessary energy consumption. Lowering LPD not only reduces operational costs but also contributes to achieving green building certifications like LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). These certifications are essential for organizations aiming to demonstrate their commitment to sustainability and environmental responsibility.

This article delves into the fundamentals of LPD, including how it is calculated, the importance of compliance with energy codes, and practical strategies for optimizing lighting systems to achieve both energy efficiency and sustainability goals.

Understanding Lighting Power Density (LPD)

Definition of LPD

Lighting Power Density (LPD) is a measure of the electrical power used for lighting within a specific area, expressed in watts per square foot (W/ft²) or watts per square meter (W/m²). It quantifies the energy demand of lighting systems and serves as a benchmark for evaluating their efficiency.

LPD is a critical metric for energy efficiency because it directly impacts a building’s overall energy consumption. By optimizing LPD, designers can reduce energy waste, lower utility costs, and contribute to sustainable building practices. It also plays a key role in meeting energy codes and standards, which are often prerequisites for green certifications like LEED or BREEAM.

Key Metrics and Terminology

To fully understand and optimize LPD, it’s essential to grasp a few related terms:

- Watts: The unit of power that measures the energy consumption of a lighting fixture. Lower wattage typically means less energy use.

- Lumens: A measure of the total visible light output from a source. Higher lumens indicate brighter light.

- Efficacy: The efficiency of a light source, calculated as lumens per watt (lm/W). Higher efficacy means more light is produced for less energy.

- Illuminance: The amount of light that reaches a surface, measured in lux (lumens per square meter). It determines how well-lit a space is.

These metrics are interconnected. For example, a high-efficacy light source can achieve the same illuminance with fewer watts, reducing the LPD. By balancing these factors, designers can create lighting systems that are both energy-efficient and effective for their intended purpose.

The Role of LPD in Green Building Design

Energy Efficiency

Reducing Lighting Power Density (LPD) is a key strategy for lowering energy consumption in buildings. By designing lighting systems that use less power while maintaining adequate illumination, building operators can significantly cut operational costs. For example, replacing traditional incandescent bulbs with LED fixtures can reduce wattage without compromising brightness, directly lowering the LPD.

Lower LPD also means less strain on HVAC systems, as efficient lighting generates less heat. This dual benefit amplifies energy savings, making it a cornerstone of energy-efficient building design.

Green Certifications

LPD plays a vital role in achieving green building certifications like LEED, BREEAM, and WELL. These certifications often include specific criteria for energy efficiency, and optimized LPD can contribute valuable points toward meeting those standards.

For instance:

- LEED: Credits are awarded for reducing lighting energy use below baseline levels set by ASHRAE standards.

- BREEAM: LPD optimization supports energy performance benchmarks, which are critical for high ratings.

- WELL: Efficient lighting design aligns with health and wellness goals by minimizing glare and improving visual comfort.

By meeting or exceeding these requirements, buildings not only earn certifications but also enhance their marketability and long-term value.

Sustainability Goals

Optimizing LPD is a practical step toward reducing a building’s carbon footprint. Lower energy consumption translates to fewer greenhouse gas emissions, especially when paired with renewable energy sources. This makes LPD a critical factor in achieving net-zero energy goals.

For example, a net-zero building might combine low LPD with solar panels to offset its energy use entirely. Such strategies align with global sustainability initiatives and demonstrate a commitment to environmental stewardship.

Compliance with LPD Standards

Overview of International and National Standards

Lighting Power Density (LPD) compliance is governed by various international and national standards designed to promote energy efficiency. Key standards include:

- ASHRAE 90.1: Widely used in the U.S., it sets maximum allowable LPD values for different building types and serves as a benchmark for energy codes.

- IECC (International Energy Conservation Code): Focuses on energy-efficient design and construction, including strict LPD requirements.

- UK Part L: Regulates energy use in buildings, including lighting efficiency, to meet sustainability goals.

- Australia NCC (National Construction Code): Includes provisions for lighting energy efficiency, ensuring compliance with national sustainability targets.

These standards establish maximum LPD values, ensuring that lighting systems are both functional and energy-efficient. For example, ASHRAE 90.1 specifies different LPD limits for offices, retail spaces, and warehouses, reflecting their unique lighting needs.

Variations by Building Type

LPD limits vary significantly based on building type to balance energy efficiency with functionality. Here are some examples:

- Offices: Typically have LPD limits around 0.9 W/ft² (9.7 W/m²) to ensure adequate task lighting without excessive energy use.

- Retail Spaces: Often allow higher LPD values, such as 1.5 W/ft² (16.1 W/m²), to accommodate display lighting that enhances product visibility.

- Industrial Facilities: May have limits of 1.2 W/ft² (12.9 W/m²) or higher, depending on the specific tasks and safety requirements.

These variations exist because different spaces have unique lighting demands. For instance, retail environments prioritize visual appeal and product emphasis, while offices focus on task lighting for productivity. By tailoring LPD limits to each building type, standards ensure energy efficiency without compromising functionality.

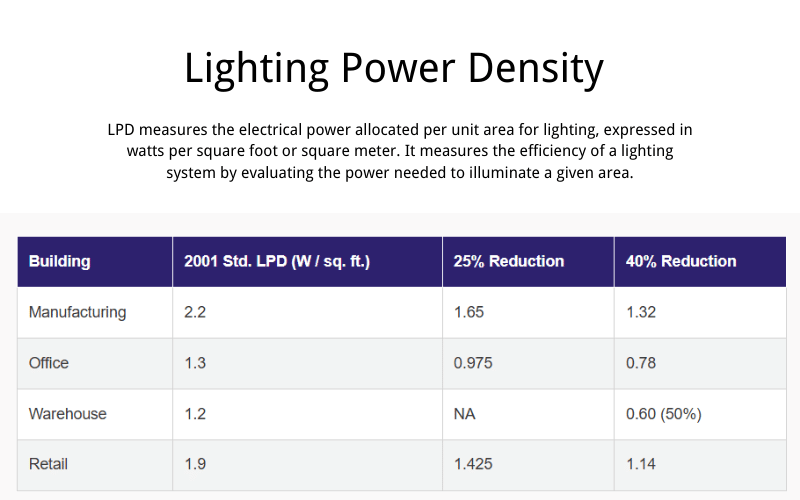

| Building | 2001 Std. LPD (W / sq. ft.) | 25% Reduction | 40% Reduction |

|---|---|---|---|

| Manufacturing | 2.2 | 1.65 | 1.32 |

| Office | 1.3 | 0.975 | 0.78 |

| Warehouse | 1.2 | NA | 0.60 (50%) |

| Retail | 1.9 | 1.425 | 1.14 |

Calculating and Optimizing LPD

Methods of LPD Calculation

Calculating Lighting Power Density (LPD) is a straightforward process that involves dividing the total wattage of all installed lighting fixtures by the area of the space. Here’s a step-by-step guide:

- Determine Total Wattage: Add up the wattage of all lighting fixtures in the space. For example, if you have 10 LED fixtures, each consuming 15 watts, the total wattage is 150 watts.

- Measure the Area: Calculate the total area of the space in square feet or square meters. For instance, a room measuring 20 feet by 15 feet has an area of 300 square feet.

- Divide Wattage by Area: Use the formula:

- LPD = Total Wattage ÷ Area

- In this example, the LPD would be:

- 150 watts ÷ 300 square feet = 0.5 W/ft²

Example Calculations:

- Office Space: A 1,000 ft² office with 800 watts of lighting has an LPD of 0.8 W/ft².

- Retail Store: A 2,000 ft² store with 3,000 watts of lighting has an LPD of 1.5 W/ft².

These calculations help ensure compliance with energy codes and identify opportunities for optimization.

Factors Influencing LPD

Several factors affect LPD, making it essential to consider them during the design phase:

- Room Size: Larger spaces may require more fixtures, but efficient placement can reduce overall wattage.

- Fixture Type: LED fixtures typically have lower wattage and higher efficacy compared to traditional lighting.

- Lighting Design: Thoughtful design, such as task lighting and daylight integration, minimizes unnecessary energy use.

- Usage Patterns: Spaces with intermittent use, like conference rooms, benefit from motion sensors and dimmers to reduce energy consumption.

By addressing these factors, designers can achieve a balance between functionality and energy efficiency.

Tools and Software

Modern tools and software simplify LPD calculation and optimization, offering accurate simulations and compliance checks:

- DIALux: A free lighting design software that allows users to model spaces and calculate LPD.

- AGi32: A professional-grade tool for advanced lighting simulations, including LPD analysis.

- Online Calculators: Many websites offer simple LPD calculators for quick assessments.

These tools help designers visualize lighting layouts, test different scenarios, and ensure compliance with energy standards, making LPD optimization more accessible and effective.

Strategies for Optimizing LPD

Energy-Efficient Fixtures

Switching to energy-efficient lighting fixtures is one of the most effective ways to reduce Lighting Power Density (LPD). LED lights, for example, consume significantly less power than traditional incandescent or fluorescent bulbs while delivering the same or better brightness. High-efficacy lighting systems, which produce more lumens per watt, further enhance energy savings. These fixtures not only lower energy consumption but also have longer lifespans, reducing maintenance costs over time.

Task Lighting and Daylighting

Incorporating task lighting and natural daylight can dramatically reduce overall energy use. Task lighting focuses illumination on specific areas, such as desks or workstations, eliminating the need to light an entire room uniformly. This approach minimizes wasted energy while improving functionality.

Daylighting, on the other hand, leverages natural sunlight to illuminate spaces. Large windows, skylights, and light shelves can bring in ample daylight, reducing reliance on artificial lighting. Pairing daylighting with automated controls ensures that electric lights dim or turn off when natural light is sufficient.

Advanced Lighting Controls

Advanced lighting controls are essential for optimizing LPD. Systems like occupancy sensors automatically turn lights on or off based on room usage, ensuring energy isn’t wasted in unoccupied spaces. Dimmers allow users to adjust light levels to suit specific tasks, reducing unnecessary brightness and energy consumption.

Daylight harvesting systems take this a step further by using sensors to measure natural light levels and adjust artificial lighting accordingly. These technologies not only improve energy efficiency but also enhance user comfort by maintaining consistent lighting conditions.

Fixture Placement and Reflective Surfaces

Strategic fixture placement and the use of reflective materials can maximize lighting efficiency. Positioning fixtures to evenly distribute light reduces the need for additional fixtures, lowering total wattage. For example, placing lights closer to work areas minimizes energy waste.

Reflective surfaces, such as light-colored walls, ceilings, and floors, amplify the effect of existing lighting by bouncing light around the room. This reduces the number of fixtures needed to achieve the desired brightness, further lowering LPD. Combining these strategies with energy-efficient fixtures and controls creates a comprehensive approach to optimizing lighting systems.

Case Studies and Lessons Learned

Real-World Examples

Office Space: Achieving LPD Compliance with LEDs

A corporate office in New York aimed to meet ASHRAE 90.1 standards by replacing outdated fluorescent fixtures with LED lighting. The project reduced the LPD from 1.2 W/ft² to 0.8 W/ft², saving 30% on energy costs annually. The use of dimmers and occupancy sensors further optimized energy use, ensuring compliance and enhancing employee comfort.

Retail Store: Balancing Aesthetics and Efficiency

A high-end retail store in London faced challenges in maintaining visual appeal while reducing energy consumption. By integrating high-efficacy LED spotlights and daylighting strategies, the store achieved an LPD of 1.4 W/ft², below the UK Part L limit. The design highlighted products effectively while cutting energy use by 25%.

Warehouse: Overcoming High Energy Demands

A logistics warehouse in Sydney struggled with high energy bills due to inefficient metal halide fixtures. Switching to LED high-bay lights and installing motion sensors reduced the LPD from 1.8 W/ft² to 1.1 W/ft². This not only met Australia NCC standards but also improved safety with better illumination.

Lessons Learned

Early Planning is Crucial

Projects that prioritize LPD optimization during the design phase achieve better results. Early planning allows for the integration of energy-efficient fixtures, advanced controls, and daylighting strategies, reducing the need for costly retrofits later.

Efficient Fixture Selection Matters

Choosing high-efficacy lighting systems, such as LEDs, is essential for lowering LPD. These fixtures provide more light with less energy, making them a cost-effective solution for compliance and sustainability goals.

Accurate Calculations Prevent Overdesign

Accurate LPD calculations ensure that lighting systems meet energy codes without overdesigning. Overestimating lighting needs can lead to higher energy use and unnecessary costs, while underestimating can compromise functionality. Using tools like DIALux or AGi32 helps achieve the right balance.

By learning from these examples and lessons, designers and facility managers can create lighting systems that are both efficient and effective.

Challenges and Solutions in LPD Compliance

Common Challenges

Over-Lighting

One of the most frequent issues in LPD compliance is over-lighting spaces. Designers often add more fixtures than necessary, leading to higher energy consumption and non-compliance with energy codes. This problem arises from outdated design practices or a lack of understanding of modern lighting technologies.

Outdated Fixtures

Many buildings still rely on inefficient lighting systems, such as incandescent or metal halide fixtures. These outdated technologies consume excessive energy and make it difficult to meet LPD standards without a complete overhaul.

Lack of Awareness

Building owners and facility managers may not fully understand the importance of LPD compliance or the benefits of energy-efficient lighting. This lack of awareness can delay upgrades and lead to missed opportunities for energy savings.

Inadequate Controls

Without advanced lighting controls, such as dimmers or occupancy sensors, energy use remains unnecessarily high. Spaces like conference rooms or storage areas often stay lit even when unoccupied, wasting energy and increasing LPD.

Innovative Solutions

Smart Lighting Systems

Smart lighting systems, equipped with sensors and automation, can dynamically adjust light levels based on occupancy and daylight availability. These systems ensure optimal energy use while maintaining compliance with LPD standards.

IoT Integration

The Internet of Things (IoT) enables real-time monitoring and control of lighting systems. IoT-connected fixtures provide data on energy use, allowing facility managers to identify inefficiencies and make informed adjustments to reduce LPD.

Advanced Controls

Technologies like daylight harvesting, motion sensors, and programmable timers help optimize lighting performance. For example, daylight harvesting systems automatically dim artificial lights when natural light is sufficient, reducing energy consumption and improving compliance.

Balancing Cost and Compliance

Phased Implementation

Upgrading an entire lighting system can be expensive. A phased approach allows building owners to replace fixtures and install controls gradually, spreading costs over time while still working toward compliance.

Leveraging Incentives

Many governments and utility companies offer rebates or incentives for energy-efficient upgrades. Taking advantage of these programs can offset the initial costs of compliance and make projects more financially viable.

Strategic Planning

Careful planning ensures that compliance is achieved without overspending. For instance, focusing on high-traffic areas first can maximize energy savings early in the process, freeing up resources for further upgrades.

By addressing these challenges with innovative solutions and cost-effective strategies, building owners can achieve LPD compliance while reaping the benefits of energy efficiency and sustainability.

Future Trends in LPD Regulations

Evolving Standards

Lighting Power Density (LPD) regulations are continuously evolving to promote greater energy efficiency. Future standards are expected to tighten allowable LPD values, pushing designers and building owners to adopt more efficient lighting systems. Dynamic metrics, such as those that account for real-time energy use and occupancy patterns, may replace static LPD limits, offering a more flexible and accurate approach to compliance.

Additionally, the scope of LPD regulations is likely to expand, covering not just indoor spaces but also outdoor lighting, such as parking lots and building exteriors. This broader focus will ensure that all aspects of lighting contribute to energy savings and sustainability goals.

Impact of Technology

Advances in lighting technology are reshaping the landscape of LPD compliance. LED systems, already a cornerstone of energy-efficient design, continue to improve in efficacy, offering higher lumens per watt and longer lifespans. These innovations make it easier to meet stricter LPD standards without compromising on lighting quality.

Smart lighting systems, powered by artificial intelligence and the Internet of Things (IoT), are also playing a pivotal role. These systems can adapt to changing conditions, such as occupancy and daylight levels, in real time. By optimizing energy use dynamically, they not only reduce LPD but also enhance user comfort and convenience.

Alignment with Global Goals

LPD regulations are increasingly aligning with global sustainability initiatives, such as the Paris Agreement, which aims to limit global warming by reducing greenhouse gas emissions. By lowering energy consumption, stricter LPD standards directly contribute to these goals, helping countries transition to low-carbon economies.

For example, net-zero energy buildings, which generate as much energy as they consume, rely heavily on optimized LPD to achieve their targets. As more governments and organizations commit to sustainability, LPD regulations will play a critical role in driving the adoption of energy-efficient practices worldwide.

Conclusion

Lighting Power Density (LPD) is a cornerstone of sustainable building design, serving as a key metric for energy efficiency and environmental responsibility. By measuring and managing the energy used for lighting, LPD helps reduce energy waste, lower operational costs, and support global sustainability goals.

Optimizing LPD offers a range of benefits, from significant energy savings to enhanced compliance with evolving energy codes and green certifications. Efficient lighting systems not only reduce utility bills but also improve occupant comfort and productivity. Additionally, meeting LPD standards demonstrates a commitment to sustainability, boosting a building’s market value and reputation.

To stay ahead of tightening regulations and rising sustainability expectations, designers and stakeholders must embrace advanced technologies and innovative strategies. Adopting energy-efficient fixtures, smart lighting controls, and thoughtful design practices will ensure compliance while maximizing energy savings. Now is the time to lead the way in creating energy-efficient, future-ready buildings.

Frequently Asked Questions

Q: What is lighting power density (LPD)?

A: Lighting Power Density (LPD) measures the amount of electrical power used by lighting equipment per unit area, expressed in watts per square foot or square meter. It is a critical metric in building energy codes, helping to estimate the energy consumption of lighting systems based on the building’s area and design typology.

Q: How do calculation methods affect lighting power density?

A: Calculation methods for lighting power density depend on the building’s type, intended use, and applicable energy codes. For example, the space-by-space method allows designers to tailor lighting designs to specific areas, reducing overall energy consumption while meeting the unique needs of each space.

Q: What is the lighting power density allowance (LPA) for different building types?

A: Lighting Power Density Allowance (LPA) refers to the maximum allowable LPD for specific building or occupancy types, as defined by energy codes like ASHRAE 90.1. For instance, commercial buildings typically have different LPA limits compared to residential buildings, ensuring energy-efficient lighting while maintaining adequate illumination levels.

Q: In what ways can optimizing LPD improve energy efficiency?

A: Optimizing LPD improves energy efficiency by reducing the electrical power required for lighting. Using energy-saving technologies like LEDs and strategically arranging fixtures ensures effective illumination while minimizing energy consumption.

Q: What are the benefits of using LED lighting in relation to LPD?

A: LED lighting helps achieve lower LPD values by consuming less power per square foot compared to traditional lighting systems. LEDs also enhance energy efficiency, reduce operational costs, and support sustainable lighting designs.

Q: How does the room cavity ratio impact lighting design and LPD?

A: The room cavity ratio influences how light is distributed within a space. Larger room cavity ratios can improve illumination levels, but designers may need to adjust the lighting power density to maintain energy efficiency and meet design requirements.

Q: What role do lighting controls play in managing power densities?

A: Lighting controls, such as dimmers, occupancy sensors, and daylight sensors, help manage power densities by adjusting lighting levels based on occupancy and available daylight. These controls reduce energy use and make it easier for buildings to comply with LPD regulations.

Q: How do building energy codes influence lighting power density calculations?

A: Building energy codes, such as IECC and ASHRAE 90.1, establish rules for calculating lighting power density. These codes set minimum and maximum allowable LPD values for different space types, ensuring lighting systems use energy efficiently while maintaining necessary illumination levels.