The advent of light-emitting diode (LED) technology has fundamentally transformed light production by delivering superior energy efficiency, prolonged service life, and compelling design adaptability. Nevertheless, peak performance and protracted bulb lifetime continue to be contingent upon junction temperature, the ambient heat executed by the semiconductor crystal itself, as well as by ancillary electronics—chiefly, the LED driver and power supply. Mastery of thermal dynamics is, therefore, mandatory across residential, commercial, and outdoor implementations. This article analyzes temperature’s differential influence on LED efficacy and driver behaviour, discusses principal thermal control strategies, and specifies requisite component selection calibrated to operational context.

Table of Contents

ToggleUnderstanding LED Light and Its Performance

What Are LEDs?

Light Emitting Diodes (LEDs) constitute an energy-efficient and durable class of solid-state lighting in which light is generated by injecting an electric current through a semiconductor junction. In contrast to conventional incandescent or fluorescent lamps, which release a substantial fraction of energy as heat, LEDs redirect almost the entire energy supply into photonic output. Their compact geometry, multitude of available spectra, and variable thermal ratings permit seamless integration into residential, commercial, and outdoor applications, enhancing both illumination and optical versatility.

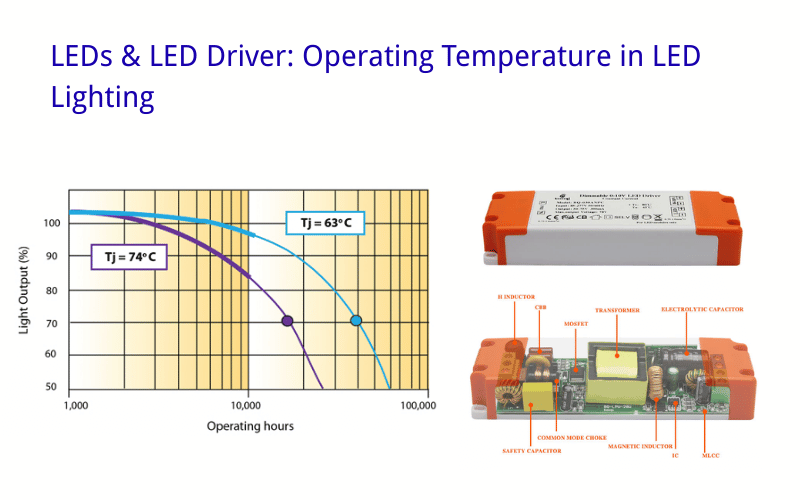

How LED Performance Is Affected by Temperature

Thermal conditions exert a decisive influence on the luminous efficacy and operational lifespan of LEDs. Elevated junction temperature diminishes output power, shifts chromaticity, and accelerates the aging of semiconductor and phosphor domains within the device structure. Elevated heat impairs carrier recombination efficiency, causing lumen depreciation and greater current-induced thermal resistance, both of which can curtail usable service life. Conversely, cryogenic or near-ambient conditions may improve the elemental efficiency of the LED material, yet ancillary systems—including LED drivers, capacitors, and heat sinks—can become error-prone, thereby illustrating the interplay of LED and peripheral thermal tolerance.

Temperature Range for Optimal LED Functionality

LEDs exhibit peak efficiency and longevity when confined to their designated temperature window, frequently cited as -20°C (-4°F) to 50°C (122°F), though variations exist among different models. Adopting the following protocols will promote stable thermal environments:

- Employ High-Performance Heat Sinks: Intelligently designed sinks transport thermal energy away from the LED junction. Utilize sinks with significant mass and surface area, oriented to capitalize on natural or forced convection currents.

- Guarantee Ample Airflow: Fixtures must be engineered for free air circulation. Sealed luminaires trap thermal energy, compromising component integrity. Employ vents—preferably at the top apron—and orient the assembly to minimize recirculation.

- Select Environment-Specified Products: For installations subjected to ambient extremes, procure LEDs rated for those conditions. Options such as outdoor-rated, high-ambient, or cold-region luminaires contain bespoke thermal and optical engineering suitable for the environment.

- Track Local Thermal Environment: Utilize infrared thermography or thermocouple sensors to catalog ambient conditions. In recessed, or micro-environment applications where material convective mass and ambient mass are minimal, thermal steering becomes indispensable.

Executing these thermal management strategies will sustain optical output, energy efficiency, and operational lifetime of the solid-state illumination architecture. Further operational datasets or design calibration spreadsheets are available upon request.

The Role of LED Drivers in Lighting Systems

What Is an LED Driver?

An LED driver serves as the pivotal interface between the LED light source and the power supply, converting mains or low-voltage electricity into a regulated, appropriate signal for the fixture. By supplying either a constant current or a constant voltage as required, the driver compensates for the inherent variance in LED forward voltage drop across temperature and aging, thereby stabilizing output light levels. Without this active regulation, an LED may experience unwanted modulation, exceed thermal limits, or suffer irreversible damage within a short operational lifetime. Additionally, driver circuitry often incorporates protective features—over-voltage, over-current, thermal, and surge suppression—collectively enhancing the fixture’s robustness and extending its service interval.

Constant Current vs. Constant Voltage in LED Drivers

Selection of driver topology is determined largely by the operational characteristics and physical architecture of the LED load. Constant current and constant voltage solutions are the two predominant frameworks,25 while a third hybrid class presently finds an increasing share due to its adaptable architecture. Constant current drivers maintain a pre-defined output current, permitting the forward voltage to float within the device’s safe operating range. This is particularly advantageous in configurations where thermal tracking is critical, such as architectural downlights and high-intensity spotlights.

By securing a narrow output current band, the thermal load on the LED assembly is stabilized, minimizing color shift and extending luminous flux maintenance schedules. At present, the power-and-lighting industries have largely standardized the current-driving profile of 10–30 mA, which orients the driver around the nominal luminous flux fold of the typical high-efficacy chips. Constant voltage drivers—especially in non-intuitive archways, variable voltage out, and tunable color temperature—maintain tighter voltage settings to handle limited thermal compensatory paths.

Constant Voltage LED Drivers: These units maintain a constant output voltage while allowing the load current to fluctuate, making them ideal for LED configurations that integrate internal current limiting, such as LED linear strips or discrete modules. Due to their output characteristics, constant-voltage drivers are frequently deployed in decorative or ambient lighting applications where color and intensity uniformity are prioritized.

Selecting the appropriate driver topology is critical to achieving the manufacturer-specified LED performance. Incorrect pairings—whether excessive voltage, insufficient regulation, or mismatched electrical noise profile—can result in abbreviated service life, color drift, or irreversible thermal damage to the LED junction.

Influence of Ambient Temperature on LED Driver Reliability

Ambient temperature is a principal determinant of the functional and enduring performance of LED drivers. Elevated thermal conditions accelerate the aging of internal passive components, particularly electrolytic and ceramic capacitors, thereby degrading efficiency and shortening mean time to failure. Conversely, excessively low ambient temperatures may impair the internal regulation loop’s startup sequence and compromise voltage stability.

To mitigate thermal risks, practitioners should enact the following:

- Choose Drivers with Specified Temperature Ratings: Procure drivers with a stated ambient operating range that envelopes the projected temperature envelope, such as –20 °C to +50 °C.

- Ensure Proper Airflow: Position drivers in regions characterized by unobstructed airflow to limit steady-state overheating and to maintain thermal equilibrium.

- Incorporate Thermally Resilient Design Elements: For applications subject to persistent elevated temperatures, specify drivers constructed with high-temperature substrates and low-DA dielectric capacitors, thus extending reliability and service life.

- Observe Ambient Conditions: Regularly check the temperature immediately surrounding the LED driver, particularly within tight enclosures or in outdoor luminaires, to prevent the internal thermal rating from being exceeded.

Recognition of the LED driver’s function, coupled with diligent control of the environment in which it operates, enables sustained efficiency and durability within LED luminaires.

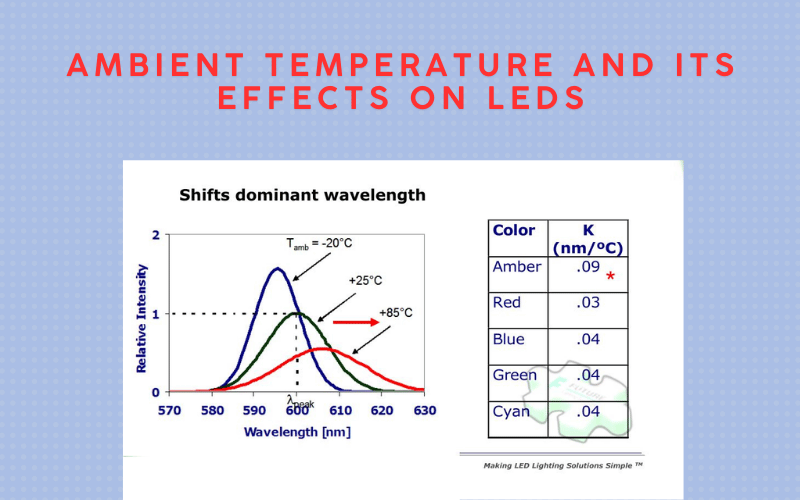

Ambient Temperature and Its Effects on LEDs

Understanding Ambient Temperature

Ambient temperature signifies the thermal condition of the space in which an LED assembly operates. It exerts considerable influence over performance, efficacy, and longevity. Unlike legacy lighting technologies, LED devices display marked sensitivity to thermal variations, given that their constituent materials—including semiconductor junctions and power-control circuitry—respond unfavourably to both elevated and lowered temperatures. Preserving an environment characterised by an intended temperature range is therefore essential for guaranteeing that light-emitting diodes operate at peak efficacy and sustain uniform lumen output over the designated life cycle.

How High Temperatures Affect LED Systems

Elevated ambient temperatures degrade LED performance through several interrelated mechanisms:

- Efficiency Decline: At elevated temperatures, quantised carriers in the semiconductor lattice exhibit diminished light-emitting efficacy, necessitating a proportionate rise in input power without a concurrent increase in optical output, thus degrading overall luminous efficacy.

- Accelerated Component Degradation: Vertically integrated devices, along with their phosphor layers, undergo thermal aging accelerated by prolonged exposure to elevated temperatures. The resultant increase in defect densities and alloy interdiffusion leads to evident lumen depreciation and hardware failure.

- Spectral Drift: Temperature coefficients intrinsic to the gain medium and phosphor films introduce thermal broadenings in the emission spectrum, shifting correlated colour temperature and disturbing colour rendering fidelity. Such drift produces undesirable visual and branding inconsistencies.

- Power-Management Compromise: The semiconductor drivers, which condition voltage and current, exhibit diminished thermal margins at elevated ambient temperatures. Thermal runaway, characterised by runaway junction temperatures, may precipitate premature power supply failure, cascading thermal and electrical stresses to the light-emitting assembly.

Techniques for Minimizing Thermal Stress in LED Lighting Assemblies

To counteract excessive heat accumulation and maintain peak LED efficacy, the following methods should be applied:

- Incorporate Thermal Sinks: Affix engineered heat sinks to the PCB or directly to the LED package to transport absorbed heat away, thereby lowering junction temperatures without significantly enlarging the fixture footprint.

- Facilitate Airflow: Design or select enclosures that provide unobstructed airflow. Virtually or physically ventilated housings broaden convective heat transfer, averting heat trapping that elevates board and optic temperatures.

- Opt for High Tj Rated Components: Procure LED devices characterized by elevated maximum junction temperature (Tj) ratings and that have encapsulation and wire-bond materials engineered for thermal and chemical resilience.

- Regularly Assess Ambient Thermal Loads: Use calibrated sensors or thermal imaging to survey the fixture environment, focusing attention on elevated ambient zones in transportation, parking structure, or pilon mounted applications.

- Implement Active Thermal Management: Deploy LEDs equipped with on-board thermal controllers that modulate drive current, pulse width, or color temperature when pre-defined thermal setpoints are reached.

Application of these thermal strategies, when calibrated to specific environment and use-case temperatures, will lead to robust, long-lived LED performance.

LEDs in Street Lighting Applications

Advantages of Using LEDs in Street Lighting

The widespread deployment of light-emitting diodes (LEDs) is modernizing municipal street lighting, imparting multiple advantages in energy, maintenance, safety, and environmental impact. The most significant benefits may be summarized as follows:

- Energy Efficiency: A comparative analysis reveals that LEDs require one-third or less of the energy consumed by high-pressure sodium or metal halide lamps, thereby achieving substantial cost savings on electricity for city and regional budgets over the life cycle of the installation.

- Long Lifespan: The rated operating life of modern LED modules ranges from 50,000 to 100,000 hours, depending on thermal management and driver quality. such high durability decreases the frequency of lamp replacement, curtails long-term maintenance expenditures, and reduces the number of road closures and traffic disruptions caused by urgent repair visits.

- Improved Visibility: The spectral characteristics of LEDs allow for an increase in lumen-per-watt efficiency while preserving distinct color rendering. The result is homogeneous, glare-controlled illumination that is perceptively brighter to the human eye, thus elevating safety for both vehicular and pedestrian traffic in intersections and walkways.

- Directional Lighting: LEDs inherently emit light in a narrow beam rather than in a spherical pattern, facilitating precise optical design. This focused emission minimizes trespass light and skyglow, allowing for optimal illumination of street surfaces and reduced ecological disturbance to adjacent neighborhoods.

- Environmentally Friendly: Unlike vapor lamps, LED sources are free of mercury, exempting municipal operators from hazardous waste management liabilities. Furthermore, the lower carbon intensity of energy consumption and substantially reduced life-cycle greenhouse gas emissions position LEDs as a public lighting technology aligned with sustainability goals.

Street Lighting Temperature Dynamics

LED streetlights are increasingly common in urban environments, yet their long-term reliability hinges in part upon how ambient temperature interacts with the luminous source. The following delineates the temperature-mediated performance envelope:

- Elevated Ambient Temperatures: Prolonged exposure to elevated ambient temperatures accelerates thermal stress within the LED package. This induces forward-voltage shifts, depresses efficacious output, and can precipitate premature junction failures. Carefully engineered thermal pathways—such as anodized aluminium heat sinks and thermal interface materials—are therefore indispensable to expel heat and prolong correlated colour temperature stability.

- Reduced Ambient Temperatures: In contrast, low ambient temperatures are generally beneficial to LED operation. The lattice thermal conductivity of semiconductor materials increases, which in turn lowers the junction temperature rise under identical drive conditions. The resultant boost in luminous flux efficacy renders LED technology particularly advantageous in geographic areas subject to protracted winter nights, facilitating both energy economy and improved visibility.

- Thermal Dissipation Architectures: State-of-the-art LED streetlight luminaires employ multiphasic thermal dissipation methodologies. Features including copper-core printed circuit boards, selectively ventilated modular enclosures, and phase-change materials collaboratively enhance heat diversion. These architectures are quantitatively validated through thermographic and long-term accelerated life testing, assuring operation well within manufacturer-delineated thermal tolerances.

Comparative Benefits of LED versus Legacy Lighting Systems

LED luminaires command dominant market position when appraised against legacy street-lighting technologies. The following categories yield quantifiable advantage:

- Electrical Efficiency: Solid-state diodes consume between 50 and 70 percent less active power compared to traditional high-pressure sodium and metal halide sources. Operational cost analyses at prevailing kilowatt-hour prices confirm empowered civic budgets and accelerated payback.

- Longevity of Source: Legacy sodium and halide bulbs are subject to accelerated lumen depreciation, necessitating semiannual or annual service interrupts. By contrast, LED array lifetimes of 50,000 to 100,000 hours at high-RoHS junction temperatures substantially lower the burden of relamping and associated labour, lift, and material costs.

- Spectral Fidelity and Uniformity: LEDs deliver engineered spectral output favourable to human colour perception and crime deterrence, in contrast to the uneven, spectrally deficient yellow of mercury and sodium lamps. The resultant luminance and colour uniformity enhance way-finding and vehicular contrast, thereby increasing perceived and measurable roadway safety.

- Longevity: Light-emitting diodes are engineered to withstand mechanical shocks and to perform effectively under temperature and humidity extremes, thereby delivering dependable illumination in exposed urban settings.

- Ecological Safety: Conventional sodium and mercury vapor sources incorporate toxic agents such as mercury, whereas solid-state lighting sources omit these hazardous constituents and are designed to facilitate end-of-life material recovery.

The replacement of legacy street fixtures with solid-state technology enables municipalities to heighten nighttime security, achieve significant operating savings, and advance goals of environmental stewardship in a single operational step.

Power Supplies and Their Importance in LED Systems

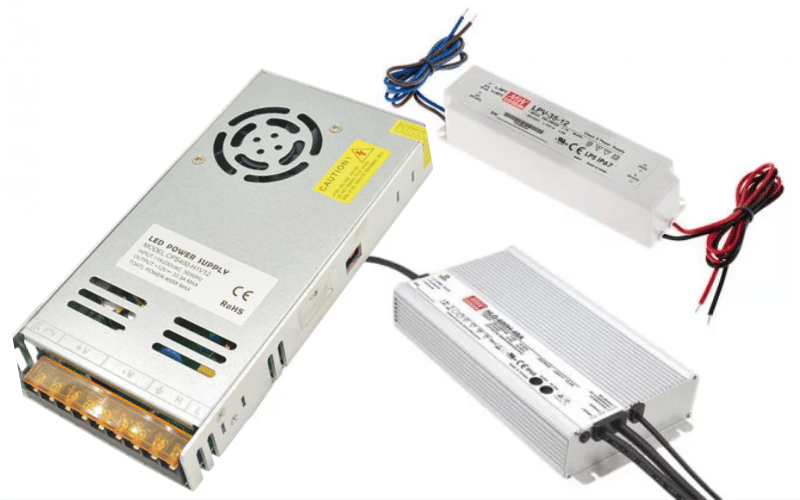

Types of Power Supplies for LED Lighting

Power supplies, frequently designated as LED drivers, serve an indispensable function within LED architectures. Their principal role is to control both the current and the voltage supplied to the semiconductor light sources, thereby ensuring that the system operates within its prescribed safety and efficiency thresholds. Power supplies for LED systems can be categorised primarily into two classes:

- Constant Current Supplies: This configuration maintains a predetermined current, permitting the output voltage to self-adjust as temperature and load conditions fluctuate. Such supplies are indispensable in installations where precise current monitoring is requisite to achieve uniform luminous output and to mitigate thermal accumulation. Typical applications include canned downlights, precision focus luminaires, and high-intensity LED modules.

- Constant Voltage Supplies: Contrarily, this type stabilises the output voltage and permits the load current to deviate as dictated by dynamic conditions. Such a driver is appropriate for LED assemblies that incorporate integrated current-limiting circuitry, a feature common in flat LED strips and decorative accent luminaires. Constant voltage supplies are conventionally offered in standard output voltages, commonly 12V and 24V.

The selection of the appropriate driver is strictly contingent upon the electrical and thermal profiles of the LED system under consideration. An ill-matched driver can precipitate accelerated degradation, compromised photometric performance, or catastrophic device failure.

Influence of Power-Supply Temperature on LED Operational Life

The thermal environment of a power supply is a critical determinant of LED system reliability and useful lifespan. The following principles illustrate the relationship between temperature and LED degradation.

- Elevated Ambient Temperature: When the ambient temperature surrounding the power supply exceeds the manufacturer’s specifications, internal components, particularly electrolytic and ceramic capacitors, may experience accelerated aging. A decline in capacitance and ESR performance leads to diminished voltage regulation, ripple performance, and increased output noise, which directly shorten LED junction life.

- Reduced Ambient Temperature: Ambient conditions that approach the lower design limit may yield differential thermal distributions across the power supply, resulting in elevated start-up times, lower output voltage stability, and increased inrush current effects. Extended time in this state can, therefore, adversely impact output fidelity, in some cases damaging the LED drive circuitry over repeated on/off cycles.

- Thermal Management Performance: Vending providers of power supplies now incorporate advanced thermal management features, including forced or passive thermal management, thermal shutdown, output power derating, and redundancy signaling circuits. When properly applied, these mechanisms provide the power supply the thermal headroom necessary to deliver maximum reliability across the full ambient spectrum.

Compliance with the manufacturer-defined operating thermal envelope is therefore obligatory and constitutes an essential performance verification step. When the ambient conditions encountered in the intended installation do not fall within this envelope, supplementary thermal modulators, including intercooling, mounting on thermally conductive substrates, and use of climate-controlled interiors, should be adopted.

Choosing the Right Power Supply for LED Applications

The efficacy and longevity of an LED system hinge to a considerable extent on the selection of an appropriate power supply. The following factors warrant close examination:

- Compatibility: Confirm that the power supply delivers the specific voltage and current stipulated by the LED circuit. A constant current source is mandatory in cases where the LED assemblies lack internal regulation; conversely, a constant voltage source is suited for standard LED strip assemblies that rely on external input.

- Wattage Capacity: The supply’s rated output should comfortably exceed the cumulative power demand of the LED load by a minimum of twenty percent. Allocating this safety margin averts thermal stress and guards against potential overload during peak operating conditions.

- Operating Temperature: Employ power supplies engineered for the ambient thermal limits expected in the application. Outdoor or industrial settings, for instance, may require units that incorporate advanced thermal management, such as forced ventilation or external heatsinking.

- Dimming Functionality: When the fixture employs dimming, verify that the supply supports the intended method, be it PWM (Pulse Width Modulation), TRIAC, or another protocol. Incompatibilities may produce flicker or, in extreme cases, damage.

- Regulatory Compliance: Prioritize units bearing recognized safety and environmental certifications, such as UL, CE, or RoHS. These markings serve as proxies for robust construction and adherence to relevant safety and electromagnetic interference standards.

Meticulous attention to these criteria will decisively extend the operational efficiency and service life of your LED lighting installation.

Frequently Asked Questions

Q: What is the operational temperature envelope for light-emitting diodes deployed in roadway illumination?

A: The operational temperature envelope for roadway LEDs is generally fixed between -40°C and 85°C. Operative temperature must be minimized and sustained within this range to preserve peak efficiency and the anticipated duration of the light source. Prolonged exposure to elevated thermal levels induces thermal strain, accelerates component degeneration, and progressively lowers photometric efficiency within the entire luminaire system.

Q: In what manner do elevated thermal conditions impact solid-state lamp performance?

A: Elevated thermal conditions elevate the junction temperature of LED chips, manifesting as diminished luminous output, decreased efficiency, and a contracted operational lifetime. The performance of the device exponentially deteriorates as thermal levels ascend. Therefore, structured thermal governance, achieved through the utilization of thermally conductive substrates and effective heat sink geometries, is imperative to contain and moderate adverse temperature rises.

Q: How do modular LED drivers contribute to the thermal stability of the luminaire assembly?

A: LED drivers monitor and dynamically constrain the electrical operating parameters—both current and voltage—so that luminous devices function within permissible thermal thresholds. By delivering a stable current, the driver preempts elevated thermal excursions, extends the operational longevity of the LEDs, and enhances the overall energy efficiency of the roadway luminaire assembly.

Q: Why does ambient temperature matter for the operation of LEDs?

A: Ambient temperature serves as a crucial determinant of LED operation. Elevated ambient temperatures elevate thermal stress on LED packages, resulting in diminished optical output, decreased electrical efficiency, and an abbreviated service life. When specifying LED street-light luminaires, engineers must incorporate the maximum expected ambient temperature of the installation corridor.

Q: What strategies enhance thermal management in LED street-lighting luminaires?

A: Effective thermal management of street-lighting LEDs is accomplished by the integration of heat sinks, geometrical optimization of the luminaire housing to promote convective and radiant airflow, and the deployment of advanced phase-change materials or liquid-cooling ducts in higher-wattage models. Each measure controls heat accumulation, thereby maximizing the optical and thermal reliability of the source.

Q: How does sustained high temperature affect LED driver longevity?

A: Continued high temperatures adversely affect the ageing profiles of LED driver circuits by accelerating the degradation of passive components, predominantly electrolytic capacitors, voltage regulator circuits, and passive inductors. Such thermal stress manifests in decreased conversion efficiency and, in extreme cases, complete failure. Specification of drivers exhibiting wide allowable temperature ranges, supplemented by thermal management strategies, is essential to achieving field reliability and service life.

Q: Why is it critical to track the temperature of LED devices during operation?

A: Systematic temperature measurement of LED components mitigates the risk of thermal overload, thus sustaining stable functionality in the emitted light. Elevated junction temperatures impair luminous flux, decrease efficacy, and accelerate device degradation. By routinely assessing thermal parameters, latent failures can be addressed in a timely manner, thereby prolonging service life and guaranteeing dependable optical characteristics.

Q: In what manner do LED driver circuits influence the thermal profile of the light-emitting diodes?

A: LED power supplies condition the input power to match the photometric load, thereby optimizing energy transfer and limiting thermal energy coupled to the LED junction. Deficiencies in power supply design, such as inadequate current regulation or excessive ripple, can elevate the thermal state of the device, which, in turn, compromises optical output stability and drastically shortens operational endurance.

Q: How do variations in temperature correlate with the emitted luminous flux of LED systems?

A: Thermal fluctuations exert measurable control over the luminous efficacy of LED devices. An increase in chip temperature results in a decreased ratio of electrical energy converted into optical energy, leading to diminished lumen output. Therefore, thermal stabilization is a requisite condition for predictable and uniform luminous performance in solid-state lighting applications.

Concluding Summary:

Temperature control emerges as the decisive factor governing sustained output, peak efficiency, and maximized lifetime of LED lighting infrastructures. A comprehensive view ranges from the influence of ambient thermal conditions on the junction itself to the imperative of confining driver and supply electronics to manufacturer-prescribed thermal envelopes. When supported by judicious thermal management—commonly by affixed heat sinks, well-designed airflow, and to-rated hardware—systems are hedged against thermal degradation. The consensus applies universally, reaching from urban streetlight arrays to factory shop floors to residential corridors. Therefore, the allocation of thermal concerns is not merely prudent; it is the precondition for enduring and responsible LED illumination.