Street lighting ensures safety, improves visibility, and creates a sense of security in public spaces. It’s a cornerstone of community well-being.

LED technology has revolutionized street lighting, offering benefits such as energy efficiency, longer lifespans, and reduced maintenance costs. Cities worldwide have adopted LEDs to save energy and enhance sustainability.

Even with these advantages, LED street lights still face challenges. Issues such as flickering, dimming, and early failure can compromise reliability. Poor-quality components, installation errors, and environmental factors often cause these problems.

This article explores common LED street light issues, their causes, and practical solutions. If you’re looking to improve performance and reliability, you’re in the right place.

Table of Contents

ToggleCommon Issues That Can Dim Your Solar Street Lights

Solar street lights are designed to reliably illuminate streets and pathways, but even the most advanced systems can encounter problems. Let’s explore the key issues that can affect their performance and how to address them effectively.

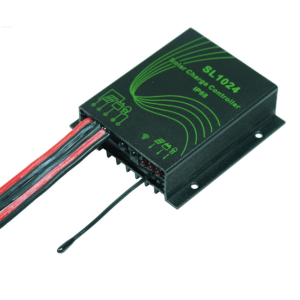

Power Supply Failures

The power supply, or driver, is the lifeline of your solar street light, converting AC power into the DC voltage needed to run the LEDs. However, it’s also one of the most common points of failure. Overheating due to poor heat dissipation, voltage spikes from unstable power grids, and the natural degradation of electrolytic capacitors over time are frequent culprits. In some cases, low-quality components used during manufacturing exacerbate these issues. When the driver fails, you may notice flickering lights, dim brightness, or even a complete system shutdown. To prevent these problems, prioritize high-quality drivers with robust thermal management and surge protection.

LED Chip Degradation: When the Light Fades Too Soon

LED chips are the heart of your solar street light, but they’re susceptible to heat and electrical stress. Without proper thermal management, excessive heat can accelerate chip degradation, leading to reduced brightness and shorter lifespans. Manufacturing defects or inconsistent chip quality can also cause premature failures, as can current overloads from faulty drivers. These issues often manifest as dimming, color shifts, or dark spots where individual chips have failed. To ensure longevity, invest in LEDs with proven thermal performance and pair them with reliable drivers to avoid current surges.

Circuit Board and Connection Defects

The Printed Circuit Board (PCB) is the backbone of your solar street light, connecting all components and ensuring smooth operation. However, poor soldering or weak connections can lead to microfractures, especially in high-vibration environments such as busy streets. Moisture intrusion, particularly in coastal or humid areas, can corrode connections and cause intermittent operation or complete circuit failure. These issues often go unnoticed until the light stops working altogether. To mitigate these risks, opt for PCBs with high-quality soldering and protective coatings to guard against environmental damage.

Keeping Your Solar Street Lights Reliable

Understanding these common failure points is essential for maintaining the performance of your solar street lights. By choosing high-quality components, ensuring proper thermal management, and conducting regular maintenance, you can significantly reduce the risk of failures and keep your lights shining bright for years to come.

Structural and Environmental Challenges in LED Street Lights

The design of an LED street light is just as crucial as its internal components. Structural and environmental factors, such as abysmal thermal management, can significantly impact performance and lifespan. Let’s take a closer look at why managing heat is so critical and how to address common issues.

Why Thermal Management Matters

LED electronics are susceptible to heat. Without proper thermal management, even well-designed systems can fail prematurely. A reliable LED street light depends on adequate heat sinking to keep components cool and functioning properly.

Common Causes of Poor Heat Dissipation

Several design and environmental factors can interfere with heat dissipation. One common issue is the use of heat sinks that are too small or made from low-quality materials. These cannot dissipate heat effectively, leading to overheating.

Another problem is poor contact between the LED modules and the heat sink. This often occurs due to improper assembly or the use of low-grade thermal interface materials, which reduce heat transfer efficiency.

Environmental factors also play a role. Ventilation fins on the heat sink can become blocked by dust, debris, or even bird nests. This traps heat and puts extra stress on the system.

The Consequences of Poor Thermal Management

When heat isn’t managed correctly, the effects can be both immediate and long-term. High temperatures accelerate wear and tear on LED chips, drivers, and other components, reducing their lifespan.

In severe cases, overheating can cause critical components to fail. This leads to costly repairs or replacements, which could have been avoided with better thermal management.

How to Prevent These Issues

To avoid these problems, focus on using high-quality materials and ensuring precise assembly. Regular maintenance is also essential to keep ventilation fins clear and heat sinks functioning effectively. By addressing these factors, you can extend the lifespan of your LED street lights and maintain their reliability.

Housing and Sealing Integrity: Protecting Solar Street Lights from the Elements

The housing of a solar street light is its first line of defense against environmental challenges. It shields sensitive components, such as drivers and LED chips, from water, dust, and debris. A well-designed housing ensures the system operates reliably over time. However, when the sealing integrity is compromised, the consequences can be severe.

Why Housing and Sealing Integrity Matter

The housing protects internal components from external elements. If this protection is breached, water and dust can enter the fixture. This can lead to performance issues, flickering lights, or even complete system failure. In harsher environments, such as coastal or industrial areas, salt air or chemicals can accelerate corrosion, further reducing the system’s lifespan.

Common Sealing Challenges

Sealing issues often arise from two main problems. First, gaskets and seals can degrade over time. This happens due to poor-quality materials, improper installation, or natural wear and tear. Second, the housing material itself can crack or deform. Extreme temperatures, UV radiation, or physical impacts are common causes of such damage.

Consequences of Compromised Sealing

When the housing or seals fail, the internal components are left exposed. Water and dust can damage drivers and LED chips, causing flickering or reduced brightness. In some cases, the system may stop working entirely. Corrosion is another major issue, especially in environments with salt air or chemical exposure. This can quickly shorten the lifespan of the light.

How to Prevent These Issues

To avoid these problems, use high-quality housing materials and durable seals. Regular inspections are also essential. They help identify cracks, degraded seals, or other vulnerabilities before they cause severe damage. By maintaining housing and sealing integrity, you can ensure your solar street lights remain reliable and long-lasting.

Physical Damage and Material Stress in Solar Street Lights

Solar street lights are constantly exposed to environmental forces. Over time, this can lead to physical damage and material stress. If left unaddressed, these issues can weaken the fixture’s structure and reduce its performance.

How Environmental Factors Cause Stress

Wind, temperature changes, and debris are the main culprits behind material stress. High winds and traffic vibrations can loosen bolts or cause parts of the housing to separate. This is known as vibration fatigue and is common in areas with heavy vehicle activity or strong winds.

Temperature fluctuations also play a role. Repeated heating and cooling cycles cause materials to expand and contract. Over time, this can lead to cracks or warping in plastic or metal components. Additionally, debris carried by wind or accidental collisions can dent or crack the fixture. Even minor impacts, if frequent, can weaken the structure.

Vulnerable Areas of the Fixture

Some parts of a street light are more prone to damage. Mounting points, for example, bear the most stress during high winds or vibrations. If these points are poorly designed or installed, they are likely to crack. Stress concentration areas, such as sharp corners or thin sections, are also weak points. These areas are more likely to fail under repeated stress.

How to Prevent Physical Damage

To reduce the risk of damage, use high-quality materials and sturdy designs. Reinforce mounting points and joints to handle vibrations and impacts. Regular inspections are also necessary. They can help identify loose bolts, small cracks, or other early signs of damage. Addressing these issues promptly can prevent more serious problems and extend the fixture’s lifespan.

Optical and Light Quality Problems in Solar Street Lights

The quality of light from a solar street light is just as important as its durability. Poor optical performance can reduce road safety, waste energy, and make installations look unprofessional. Several common issues can affect the optical components and light quality.

Lens and Diffuser Issues

The lens and diffuser are key to directing light onto the road. Over time, plastic lenses can yellow or become cloudy due to UV exposure. This reduces brightness and light transmission. Misaligned lenses, often caused by poor assembly, can create uneven light patterns. Some areas may be too bright, while others are too dim. Repeated heating and cooling cycles can also cause cracks in the lens material, further reducing its efficiency.

When these problems occur, the system struggles to provide uniform lighting. This can lead to safety concerns and higher energy use as the system works harder to compensate for the loss of efficiency.

Light Flickering Problems

Flickering is a common and noticeable issue in street lighting. It can be caused by ripple currents from a failing driver or voltage instability in areas with unreliable power. In some cases, dimming systems that are incompatible with LED drivers can also cause flickering. Flickering not only distracts drivers but also lowers the perceived quality of the light. Over time, it can lead to complaints and expensive repairs.

Color Temperature and Uniformity

Consistent color temperature is essential for a professional and cohesive look. Mixing LED fixtures from different production batches can result in noticeable color differences. Over time, individual LED chips may also shift in color due to heat or aging. This creates a patchy appearance that detracts from the installation’s overall look and can lead to stakeholder dissatisfaction.

How to Address These Issues

To prevent these problems, use high-quality optical components and ensure proper assembly during installation. Regular maintenance is also essential for catching and fixing issues early. By addressing these factors, you can maintain consistent light quality, improve safety, and enhance the appearance of your solar street lights.

Quality Control During Installation and Maintenance

Proper installation and regular maintenance are essential for the long-term reliability of solar street lighting systems. Even the most advanced fixtures can fail prematurely if these steps are not executed with care. Understanding common pitfalls during installation and maintenance can help prevent costly issues and ensure optimal performance.

Installation Challenges

Installation errors are a leading cause of early failures in solar street lights. Faulty wiring or inadequate grounding, for example, can result in electrical failures, short circuits, or even safety hazards. Ensuring all connections are secure and grounding meets industry standards is critical to avoid these problems. Another common issue is over-tightening bolts. While securing bolts is necessary, applying too much force can cause stress fractures, especially near mounting points that already endure significant stress. Using a torque wrench to apply the correct torque can prevent such damage.

Incorrect mounting angles are another frequent problem. When fixtures are not appropriately aligned, light distribution is disrupted, leaving some areas underlit and others overlit. Following manufacturer guidelines and using tools like a level can help achieve the correct alignment and ensure even illumination.

Maintenance Challenges

Even a perfectly installed system requires regular maintenance to keep it performing well. Neglecting this step can lead to avoidable issues. For instance, dust and debris often accumulate on lenses and heat sinks, reducing light output and causing overheating. Routine cleaning of these components is essential to keep the system running efficiently. Additionally, using incompatible replacement parts during repairs can compromise the system’s performance. It’s necessary to source parts from trusted suppliers and verify their compatibility with the original specifications before installation.

Ensuring Long-Term Reliability

By addressing these standard installation and maintenance challenges, you can significantly extend the lifespan of solar street lighting systems. Attention to detail during installation, combined with a proactive maintenance schedule, ensures that the system operates reliably and efficiently for years to come.

Frequently Asked Questions (FAQs)

Q: How long should an LED street light fixture last before replacement?

A: A high-quality LED street light fixture should last over 50,000 hours, which is about 10–15 years of operation. This depends on usage and environmental conditions.

Q: What standards define the proper thermal management for outdoor LED fixtures?

A: Standards like IEC 60598 and LM-80 provide guidelines for thermal management. These ensure LED fixtures maintain optimal operating temperatures, thereby extending their lifespan.

Q: Can voltage fluctuations damage brand-new LED street lights?

A: Yes, voltage fluctuations can damage LED drivers and chips, causing flickering or failure. Installing surge protectors and using high-quality drivers can help prevent this.

Q: How do you test the IP rating of an existing LED street light installation?

A: IP ratings are tested by simulating environmental conditions, such as water spray or dust exposure. This ensures the fixture’s seals remain intact and effective.

Q: What is the difference between lumen depreciation and catastrophic failure in LEDs?

A:

- Lumen Depreciation: A gradual reduction in brightness over time.

- Catastrophic Failure: A complete loss of light output due to component failure.

Conclusion

LED street lights offer tremendous benefits, but their reliability depends on addressing common quality issues head-on. Prioritizing robust component selection, precise thermal management, and strict ingress protection significantly reduces failure rates. Additionally, rigorous pre-installation testing and adhering to proper mounting protocols ensure the long-term performance of public lighting systems.