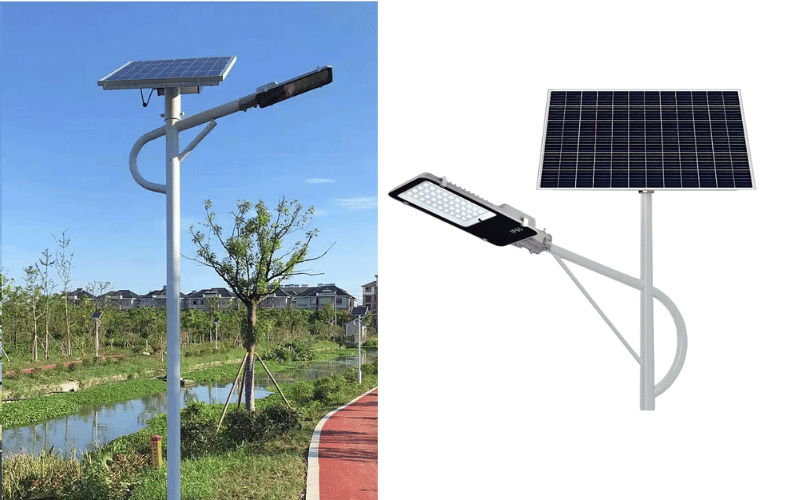

Solar street lights have transformed the paradigm of outdoor illumination by delivering a renewable, high-efficiency, and environmentally friendly substitute for legacy lighting systems. By capturing solar energy to power advanced LED fixtures, these systems are suited to settings including metropolitan corridors, countryside paths, and isolated villages lacking grid electricity. Integrated components—photovoltaic panels, energy-storage batteries, and high-intensity LEDs—interoperate to yield persistent, glare-free illumination while minimizing operating costs and carbon emissions. This manual examines the indispensable function of support poles within solar street lighting architectures, specifying material varieties, design attributes, mounting techniques, and stewardship guidance to assure peak operating efficacy and enduring service life.

Table of Contents

ToggleUnderstanding Solar Street Lights

Solar street lights exemplify a forward-looking and resource-efficient approach to outdoor illumination. By converting solar radiation to electrical energy, these systems empower LED luminaires and obviate the need for conventional power supplies. Solar-luminaire installations are being adopted not only in metropolitan centres but also in peri-urban and provisional settings, including pathways, parks, and along corridors where the electrical grid is inaccessible or economically prohibitive.

What are Solar Street Lights?

Solar street lights are integrated lighting units encompassing photovoltaic modules, energy-storage subsystems, and high-efficacy light-emitting diodes. Affixed to street-lighting masts, PV panels capture solar insolation during daylight, convert it to direct current, and direct the current to recharge contained batteries. Once photoperiod transitions, the charge is released to LEDs, which radiate diffuse light along roadways and pedestrian thoroughfares, mitigating the reliance on distributed or ducted utility resources. The technologies collectively yield a durable and low-carbon alternative to grid-reliant street illumination.

Benefits of Solar Power in Street Lighting

- Energy Efficiency: The lights exploit continual solar input, accomplishing the dual objectives of renewable-sourced operation and the diminished draw of any grid support previously required.

- Environmentally Friendly: By forgoing conventional electricity during operation, overall carbon discharge from street-light systems is markedly attenuated, thereby advancing broader atmospheric and ecological transition goals.

- Cost Savings: After initial capital, which is often offset through aggregated life-cycle evaluations, the systems incur practically zero electrical feed costs; for this reason, their financial attractiveness rises across prolonged urban- and rural-scale installations.

- Minimal Maintenance Demand: Featuring a streamlined design with fewer mechanical components and engineered for extended longevity, solar-powered street illumination systems are unlike conventional fixtures that necessitate frequent upkeep.

- Energy Autonomy: Their reliance on photovoltaic generation allows solar street lights to function reliably in remote or grid-deficient zones, delivering uniform illumination irrespective of commercial power disruptions.

Key Elements of a Solar Street Lighting Assembly

- Photovoltaic Array: The array performs the primary function of solar-to-electric conversion, with premium, glass-covered monocrystalline or polycrystalline cells maximizing energy harvest throughout varied climatic conditions.

- Electrical Storage Unit: A sealed lithium-ion or sealed lead-acid battery bank accumulates the harvested energy, liberating it to the light engine after sunset in a controlled, steady discharge.

- Solid-State Luminaire: The luminaire, a high-efficacy light-emitting diode array, offers superior lumen-per-watt output and a rated lifespan markedly transcending that of high-pressure sodium or metal halide equivalents.

- Power Management Circuitry: A microprocessor-based control unit orchestrates the energy interplay, optimizing charge acceptance, discharge profile, and day/night transition, while employing protection algorithms to circumvent over-charge and depth-of-disurface limitations.

- Support Assembly: A structural steel or aluminum pole, coupled with a bracket system of hot-dip galvanized steel, securely integrates and orients the photovoltaic array, luminaire, and storage unit at the appropriate tilt and azimuth for maximal energy capture and mechanical stability.

Choosing an Appropriate Pole for Solar Street Lighting Systems

The selection of a pole for a solar street-lighting deployment is a fundamental decision that influences structural integrity, energy optimisation, and system lifespan. Beyond merely providing physical support, the pole must carry solar modules, energy-storage collaterals, and light sources while resisting climatic loads, such as wind and precipitation, that are typical of the intended site.

Key Parameters for Pole Selection

- Pole Height: A definitive determinant of luminous spread, pole height is calibrated such that elevated installations are favoured along thoroughfares and expansive public-domain zones, whereas heights commensurate with 3.5 to 5 metres are the standard for side-streets and pedestrian thoroughfares.

- Material Composition: The pole’s substrate influences mechanical performance, corrosion resilience, and overall weight. Steel, with its tensile strength, is preferred for high-load and seismic zones; aluminium delivers an advantageous strength-to-weight ratio and corrosion resilience; and reinforced concrete affords a low-requirement maintenance pathway and cost efficiency, albeit at a penalisation of overall weight.

- Aerodynamic Design: The structural section and fixture allow a calculated resistance to the prevailing wind pressure, integral in coastal, valley, and elevated regions, in order to avert buckling and fatigue.

- Service Ability: The supporting shaft must exhibit a minimum section modulus that accounts for the cumulative gravitational force of the solar array, the storage modules, and the luminous source, thus assuring a factor of safety commensurate with the relevant loading standard.

- Architectural Compatibility: In densely built and landscaped settings, the visual impact of the pole—including shape, finish, and colour—must harmonise with the surrounding architectural fabric, in parallel with performance requirements, to achieve an understated yet effective presence.

Different Types of Poles for Solar Street Lighting

- Galvanized Steel Poles: Steel poles deliver exceptional tensile strength and are corrosion-resistant when hot-dipped. A galvanized finish is standard for installations subject to salt-laden winds or industrial atmospheres, extending lifespan by decades. Their rigidity is indispensable in regions with recorded gust loads exceeding standard thresholds or where undue stress from heavy truck traffic is expected.

- Aluminum Alloy Poles: Constructed from corrosion-resistant, aerospace-grade alloys, aluminum poles combine low mass with rigidity. Their reduced conveyed loads facilitate ease of rack-and-pinion installation, making them ideal for coastal or light-industrial peripheries, where salt fog elevates corrosion risks. Maintenance is minimized to periodic cleaning, generally unnecessary in dryer, offshore applications.

- Reinforced Concrete Poles: Precast concrete offers a high-strength, low-maintenance option in regions where unit transportation logistics favor dense mass. Foundation torque sleeves are advised to accommodate loaded bending moments during cosmetic transportation. Rural apps, with low equipment density, and clustered industrial cite installations report reduced overall lifecycle cost in stacked economies of scale.

- Wood Poles: Forested and sustainably sourced poles present a minimal ecological footprint when managed with certified forestry practices. Their reinforcement with galvanized spikes or copper-azole treated alasinta boards mitigates decay, extending service life to fifteen years in temperate climates. Maintenance cycles, however, must be programmed for a service interruption, thus qualify them for selective applications.

- Hybrid Composite Poles: A market segment is emerging that marries aluminum sleeves to galvanized steel bases or tendon reinforcements, tailoring strength-for-weight ratios and cost-per-millin. Modular inserting of intelligent weight sensors, tubular fittings for antimicro-balancers or integrated lineavin E-lamps exhibits a total cost of operation parity to other solutions when lifecycle cost, delivery horizon, installation, and self-cleaning disposition are modeled.

Best Practices for Selecting the Right Solar Light Pole

- Environment Matching: Perform geospatial wind modeling, soil elasticity assays, and hourly climatic load data to align the pole choice with its specific load requirements. Peak gusts that exceed nominal seventy-mile readings, sandy soil local, or ethos regions for corrosion loading data will dictate pole diameter, steel grade, and sectional moment orientation.

- System Convergence: Confirm the selected pole’s hub height, windage, and confinement with load-carrying moment has its elevation tolerance limits; its horizontal moment tolerance, its lateral drag moment, and with supporting mechanical joints rigor classification to actual path lamp loading manage categorize with high-illuminating voltage ratios.

- Affirm Durability and Minimal Upkeep: Specify components and surface treatments engineered for extended life and resistance to elevated humidity, ultraviolet radiation, and cyclic thermal stress.

- Engage Specialized Authorities: Collaborate with reputable suppliers and structural engineers to evaluate and certify the vertical member against prevailing safety codes and functional requisites.

- Execute Prototypes Prior to Deployment: Implement static and dynamic assessments to quantify vertical stress and overturning stability, thereby validating the selected member’s compatibility with the intended photovoltaic street lamp assembly.

Installation Height of Solar Street Lights

Height is a decisive factor in the effective deployment of solar street lights, influencing uniformity of illumination, energy performance, and overall public safety. Selecting the correct mounting elevation is therefore essential for optimizing technological and environmental objectives.

Height Guidelines for Solar Street Lights

- Residential Environments: When lighting walkways, landscaped parcels, and local roadways, a mounting elevation of 3 to 5 meters (10 to 16 feet) is generally preferred. This height balancedly distributes illumination without causing excessive glare in adjacent properties.

- Urban Corridors and Parking Areas: Poles in the 6 to 9 meter (20 to 30 feet) range are recommended for city streets and parking lots. Such elevations extend the effective beam width and allow for a lower density of fixtures, thereby cutting installation and long-term maintenance costs.

- Expressways and Extensive Open Land: Roadways, manufacturing zones, and expansive public lands ideally employ fixtures mounted at 10 to 12 meters (33 to 40 feet). At these levels, the beams’ travel distance produces optimal visibility, minimizing accidents and enhancing public confidence.

Influence of Height on Energy and Performance

- Light Distribution: Elevating fixtures generally produces a wider beam at lower intensity, potentially leaving shadows in undisturbed areas. Conversely, mounting fixtures lower concentrates energy into a narrowed footprint, raising on-surface lux levels yet increasing pole density and the likelihood of shadows.

- Energy Consumption: The physical elevation of a luminance pole influences both the photometric angle and the beam spread of the emitted light. Appropriate selection of pole height restricts the superfluous dispersal of light into unproductive areas, thereby channeling illumination precisely toward the required surfaces and conserving energy.

- Shadow Reduction: If the pole height is inadequately calculated, the resulting luminaire position may produce undesired obstructions or generate uneven photometric Fields. Conversely, an appropriately specified height fosters isotropic illumination, maximizing the utility of the lighting installation.

Adjusting Installation Height for Optimal Performance

- Consider the Area’s Purpose: Align pole height with the designated functional classification of the site. For instance, pedestrian routes benefit from lower elevations, while arterial roadways demand more considerable pole height for adequate motorist visibility.

- Account for Surrounding Structures: Evaluate the vertical and horizontal relationships between the pole and potential impediments such as foliage, buildings, and infrastructure. A pole elevation safeguards against luminous shielding and ensures a clear photometric path.

- Use Adjustable Fixtures: Deploy lighting units that permit articulation of optical axis, tilt, and rotational inclination. Such flexibility compensates for vertical height variations while optimizing luminous efficiency.

- Test Before Finalizing: Implement empirical photometric measurements and empirical assessments in situ. Controlled measurements enable verification of uniformity ratios, illuminance levels, and luminaire setbacks, thereby ensuring that the as-designed height achieves the anticipated lighting and energy performance.

Best Poles for Your LED Solar Street Lights

Selecting the appropriate pole for your LED solar street lights is critical for the longevity, efficacy, and seamless operation of the lights. The solar panel, battery, and the light fixture all hang from the pole, which is subjected to the elements. Therefore, the pole should withstand the elements while providing the system support.

Best Features of Solar Lighting Poles

- Material Durability: The most protective poles are made of galvanized steel, aluminum, or concrete. Whatever the weather, these materials will withstand it. Plus, none are prone to corrosion, and longevity is guaranteed.

- Wind Load Capacity: The pole should be constructed to a specific standard in order to withstand the most common wind speeds for whichever region the structure is installed. Otherwise, the pole will be prone to great damage, or just a lack of stability, during storms or high winds.

- Height Versatility: The most useful poles will come in a plethora of heights for all kinds of purposes and installations, from residential pathways to major highways. Increased height or further adjustable height options improve flexibility.

- Lightweight Design: Poles made from aluminum are a prime example of a structure that is light in weight, and rigorous in strength. Hence, they are more efficient to carry during installations and will not destabilize the structure.

- Aesthetic Appeal: Light poles with a minimal design, and the ability to alter the colors and grafts, do not stand out too much in cities and gardens, which is a great overall improvement for the area.

Comparative Analysis of Solar Light Poles

Steel Poles

- Pros: Extremely strong, durable and, ideal for high-wind areas.

- Cons: It is heavier and might need galvanizing to avoid rusting.

- Best For: Highways, industrial zones, and regions with harsh climatic conditions.

Aluminum Poles:

- Pros: Lightweight, resistant to corrosion, and not difficult to install.

- Cons: Slightly more than steel.

- Best For: Coastal regions, city streets, and suburban areas.

Concrete Poles:

- Pros: Inexpensive and very sturdy.

- Cons: Difficult to move and heavy, making installation a challenge.

- Best For: Remote areas and industrial use.

Hybrid Poles:

- Pros: Balance the stiffness of lighter materials with the durability of heavier materials.

- Cons: Often priced higher than conventional poles of a single material.

- Best For: Many different applications that need customization.

Examples of Costs Which Are Measurable for Solar Street Light Poles

- Material Expenses: Also the least expensive, steel poles do come with the added cost of galvanization. Aluminum poles however, come with a higher price, and for that reason, they are more cost-effective over the years due to low maintenance.

- Labor Costs: Installation of lightweight poles like aluminum, is less expensive, while heavier poles like concrete, will incur added costs due to the need for specialized tools and equipment.

- Ongoing Costs: These poles minimize reconstruction costs over the years due to the use of a coating that prevents corrosion, or with material that is rust resistant.

- Customization and Design: Offering value in urban and landscaped areas, poles with unique designs and aesthetic finishes may come with a higher price, but are more valuable.

- Bulk Purchases: Large-scale acquisitions involving poles as part of a planning project often lowers the price per unit, making it more economically feasible for extensive installations.

Installing Solar Street Light Poles

Proper installation of solar street light poles is essential to ensure their stability, functionality, and longevity. Following the right steps and avoiding common errors can save time, reduce costs, and enhance the system’s performance.

Step-by-Step Guide to Solar Street Light Pole Installation

-

Site Selection:

Choose a location with maximum sunlight exposure and minimal obstructions like trees or buildings. Ensure the area is free from underground utilities before digging. -

Foundation Preparation:

- Dig a hole based on the pole’s height and weight. Typically, the depth should be 10% of the pole’s height plus an additional 2 feet for stability.

- Pour concrete into the hole to create a solid foundation. Allow it to cure for at least 24-48 hours before proceeding.

-

Assemble the Pole Components:

Attach the solar panel, battery, and LED light to the pole as per the manufacturer’s instructions. Ensure all connections are secure and weatherproof. -

Erect the Pole:

- Use a crane or manual lifting tools to position the pole upright.

- Secure the pole to the foundation using anchor bolts or brackets. Double-check the alignment to ensure it is straight.

-

Connect the System:

- Link the solar panel to the battery and LED light using the provided wiring.

- Test the connections to confirm the system is functioning correctly.

-

Final Inspection:

Inspect the entire setup for stability, proper alignment, and operational efficiency. Make any necessary adjustments before leaving the site.

Common Mistakes to Avoid During Installation

-

Incorrect Foundation Depth:

A shallow foundation can compromise the pole’s stability, especially in high-wind areas. Always follow the recommended depth guidelines. -

Poor Alignment:

Misaligned poles can affect the solar panel’s ability to capture sunlight and reduce the system’s efficiency. Use a level to ensure proper alignment. -

Loose Connections:

Insecure wiring or bolts can lead to system failures or safety hazards. Double-check all connections during installation. -

Ignoring Local Regulations:

Failing to comply with local building codes or permits can result in fines or the need for reinstallation. Always check regulations before starting. -

Skipping Testing:

Not testing the system after installation can lead to undetected issues. Always perform a thorough test to ensure everything works as intended.

Maintenance Tips for Solar Street Light Poles

-

Regular Cleaning:

Clean the solar panels periodically to remove dust, dirt, and debris that can block sunlight and reduce efficiency. -

Inspect for Damage:

Check the pole, wiring, and components for signs of wear, rust, or damage. Address any issues promptly to prevent further deterioration. -

Tighten Bolts and Connections:

Over time, bolts and connections may loosen due to environmental factors. Regularly inspect and tighten them to maintain stability. -

Monitor Battery Performance:

Test the battery’s charge and discharge cycles to ensure it is functioning optimally. Replace it if performance declines significantly. -

Trim Surrounding Vegetation:

Keep the area around the pole clear of overgrown trees or plants that could obstruct sunlight or damage the system.

Frequently Asked Questions

Q: What is the vertical dimension which should be considered for the installation of solar powered street lighting?

A: The most optimum vertical dimension for solar street lights is between 4 and 12 meters depending on the luminous efficacy and the width of the carriageway. For example, parking garages require pole heights between 8 and 10 meters in order to achieve optimal light distribution and spacial envelope illumination.

Q: What is the method for assessing the height of poles used for solar street lighting?

A: Evaluating pole height is the outcome of the illuminated region and the aim of illuminated target, the pole-spacing configuration. In urban areas pole heights of the order of 6 meters (20 feet high) is justified for very wide beam lasers, in the suburban regions much lower heights are accepted.

Q: What are the fundamental principles that govern the height of poles in solar street lighting installations?

A: Main principles revolve on the illumination of the placed poles under solar street light, climatic conditions, the angle of the roof in relation to the poles, and the direction and strength of sunlight that reaches each separate solar cell. All designs should aim to achieve the least optical loss, best illumination ratios, and best lower pole height, without violating the local standards.

Q: Does changing the elevation of street solar lights affect the distribution of light?

A: Yes, height of lamp pole is one of the key parameters affecting light distribution. Lighted up fixtures typically increase the throw of light, as well as decreases the angle of light falling onto vertical surfaces, hence light spill is reduced. However, if the height of the pole is not matched with the lamp and optic assembly, there is a chance of increased contour shadow bands. Therefore the height above ground needs to be optimized to achieve the desired light uniformity on the surface.

Q: What maintenance requirements arise at various levels of solar street lights?

A: Main issue is the type of access. Higher fixtures need to have specific procedures for maintenance, such as cleaning and replacing the lamps, especially in areas prone to corrosion further increased by wind and dirty airborne particles. Also, the height may be a factor that limits the range of motion on vehicle lifts and portable scaffolds. Maintenance of those type of platforms in cramped areas is more labor intensive and time consuming. For that reason, maintenance is a primary factor that needs to be considered for pole height.

Q: How do the weight of the solar panels impact the height of the streetlight pole?

A: The weight of the solar panel drives the configuration of the panel support structure. A tombstone of heavy, monocrystalline cells displaces a significant moment about the mounting bolt, and as such, requires a brace of shorter, monolithic, wide baseplates and stout, thick poles. Such configurations mitigate the overturning moment in lateral trimming. In contrast, light, rollable, amorphous panels may be cantilevered from longer and thinner cantilevers, however, the stability risk in sites of brutal gusts is minimal.

Q: Why do solar street lights poles need to be installed at a specific height?

A: The height of the pole corresponds to the average horizontal illuminance, optic, and solar recharge angle of the system. Low height may yield insufficient photometric uniformity in the contract zones, while too much height compresses critical zones and decreases the cumulative collected lumens. Furthermore, such compression may cause vertical glare for the users. Therefore, the installation height is the optimum intersection of luminous, structural, and ergonomic principles.

Q: What extra features do Hykoont solar street lights offer in urban and rural areas?

A: Hykoont solar street lights illuminate an area while consuming minimal energy. These lights can be mounted at different elevations and on different angles anatomically without compromising on beauty. They offer uninterrupted reliable services using algorithms which record weather patterns. These lights can be placed on any geographic location.

Concluding Summary:

In conclusion, solar street lighting represents a paradigm shift, integrating ecological stewardship, energy efficiency, and economic savings into a single turnkey package. Selecting the optimal pole is decisive for the lighting system’s structural integrity, resistance to weathering, and luminous efficacy. Choices of material—such as hot-dipped galvanized steel, extruded aerospace-grade aluminum, or reinforced-concrete composites—must be paired with precise specifications of pole height, torsional load capacity, and integration of architectural styling. Conscientious erection and periodic servicing further safeguard the dependability and operational life of the fixtures. By embedding renewable technologies into urban and rural planning, municipalities signal a commitment to ecological leadership; solar street lighting thus emerges as a viable and morally sound pathway to a luminous, sustainable future.